Driveline performance simulation

Driveline performances simulation for optimized vehicles.

Vehicle range & energy consumption Simulation.

Predictive driveline simulation

AUMOVIO Engineering Solutions enables accurate prediction of range and energy consumption through standardized test cycles (e.g., NEDC, WLTC), custom driving profiles, and real-world scenarios like top speed, acceleration, hill and curb climbs—across all development stages.

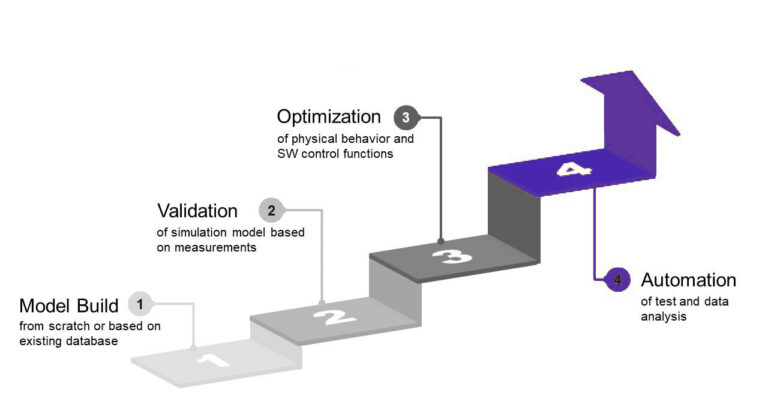

In early development, basic simulations quickly define key vehicle parameters such as topology, component sizing, gearbox ratios, and battery capacity. In later phases, advanced models incorporate detailed components and control strategies to optimize both individual systems and full vehicle performance. Our proprietary AUMOVIO simulation toolchain integrates automated optimization and result analysis for maximum efficiency.

In addition to using a standard model and control libraries, you can seamlessly integrate your own models into our simulation environment. Likewise, our component and system models can be embedded into your existing simulation tools.

With deep simulation engineering expertise, AUMOVIO Engineering Solutions supports the development of custom driveline systems tailored to your requirements and global regulatory standards.

Our solutions.

Our services

- Driveline simulations at component, system, and vehicle levels

- Basic performance simulations using standard driveline components

- Integration of third-party models into the simulation environment

- Advanced simulations for detailed component behavior and control strategy analysis

Tools & methods

- Expertise in a wide range of simulation tools

- Flexible model platform for multiple topologies, components, and control algorithms (incl. parameter sets)

- Simulation and validation aligned with industry standards

Benefits

- Early integration of software, hardware, and mechanics in simulation

- Tight collaboration between simulation and testing for effective validation

- System behavior optimization through control algorithms and calibration

- Reduced testing time and development costs

- Efficient test case and data management