With 25+ years in electric machine design and validation for automotive and motorsport, AUMOVIO Engineering Solutions partners with OEMs and integrators to deliver high-quality, cost-effective engineering.

We cover everything from concept to production-ready machines—offering electromagnetic analysis, testing, and optimization—all in-house.

Specializing in advanced solutions beyond conventional designs, we leverage deep expertise in materials, topologies, and thermal management for peak performance.

Our services

We evaluate all key data—including battery specifications, cooling requirements, packaging constraints, machine performance goals, drive cycles, NVH considerations, and cost factors—to recommend the optimal form factors and materials. Using advanced electromagnetic and thermal analysis tools, we reduce risks early in the development stage and provide FEA-based equivalent electrical models to support control engineering. Our expertise extends from technician-built prototypes to high-volume automated production, ensuring scalable manufacturing backed by extensive high-voltage know-how.

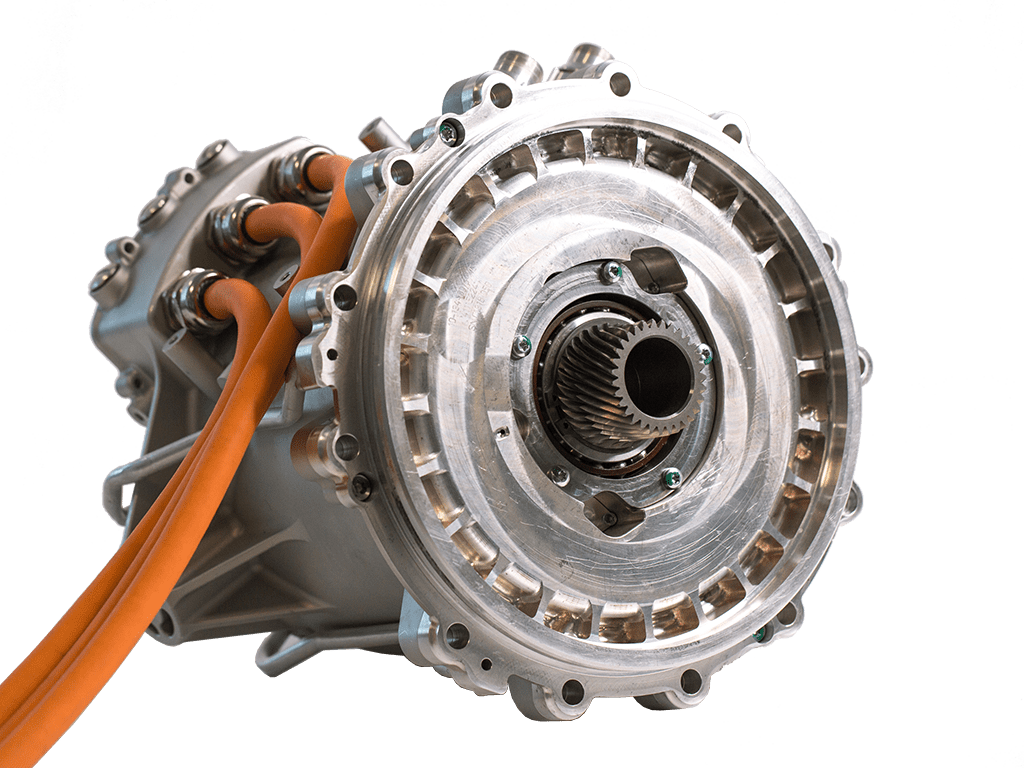

Electric motor

Facilities, tools & expertise that deliver.

Comprehensive capabilities for efficient development and reliable validation.

Our facilities

- Fully equipped prototype manufacturing workshop for high-quality, repeatable hand-built samples

- Three advanced electric machine dynamometers supporting up to 270 kW, 900 V DC link, 25,000 rpm, and 750 Nm torque for comprehensive testing and validation

Your benefits

A dedicated, multidisciplinary team of engineers and technicians using optimized tools and modern facilities, partnering closely with you to accelerate your project’s success.

Methods & tools

- Siemens Simcenter 2D & 3D electromagnetic FEA with transient motion solvers

- Ansys Motor-CAD for comprehensive motor analysis

- Proprietary in-house tools for detailed electric machine design documentation