3D thermal simulation and structure analysis

From components to complete vehicles—simulated with precision.

Optimizing performance.

As development cycles shorten and system complexity grows, simulation and virtual testing become essential. AUMOVIO Engineering Solutions delivers powerful 3D simulation capabilities tailored to your specific needs.

With our expertise, costly real-world tests—like dyno and climate chamber tests—can be minimized. Virtual optimization improves quality and accelerates development by enabling evaluation of more test scenarios. Combined with automated test evaluation and reporting, this creates significant added value.

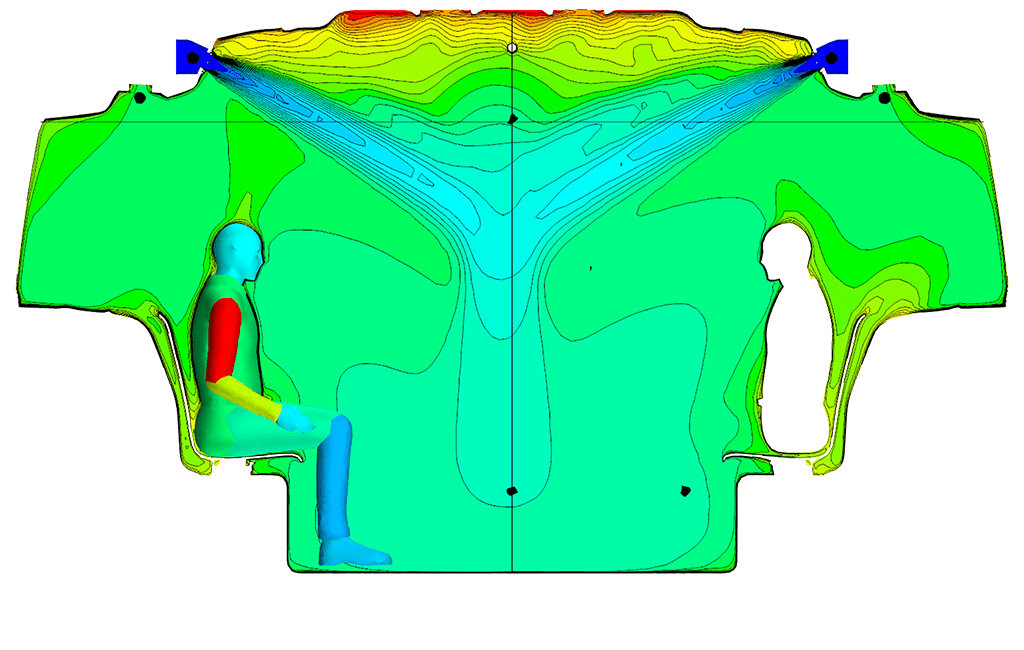

Cabin simulation – example

A key highlight is our cabin comfort simulation, which tackles complex 3D challenges like detailed geometry preparation and multi-physics fluid-solid interactions. Especially for electric vehicles, our advanced cabin control optimizes passenger comfort and extends driving range beyond basic control methods.

Thermal analysis of electronic systems – example

Modern electronics and electro-mechanical designs feature high power density and flux, causing significant heat generation that can limit performance and lifespan. Our goal at AUMOVIO Engineering Solutions is to boost system performance while reducing weight and size. Achieving this requires an integrated approach considering boundary conditions and part interactions. Here, 3D CFD simulations outperform simple calculations. AUMOVIO Engineering Solutions is ready to support you with simulation engineering to enhance mechanical and hardware design through optimized component cooling.

Structure analysis – example

An essential focus is the structural design of engine mounting parts connecting the combustion engine or electric machine to the chassis. AUMOVIO Engineering Solutions uses FEM simulations to validate static and dynamic loads with linear and nonlinear material behavior.

Optimizing these components is a core strength of our mechanical designers. Working within agile development teams, we prioritize improved part performance and weight reduction.

From components to complete vehicles.

Simulated with precision.

Our services

- 3D model creation and preparation

- Thermal simulation of critical electronic components

- Thermal and hydraulic simulation of component cooling

- Structural analysis of components and vehicle parts

- Optimization recommendations

- Support for component and system testing

- Assistance with model-based software development for thermal management (drivetrain and cabin)

- Support for software development, virtual testing, and environmental testing of software functions

Your benefits

- Reduction of testing time and number of prototype build ups

- Reduction of costs and development times

- Repeatability of virtual testing

- Possibility to adapt to different mechanic, hardware and software designs

Tools and methods

- Various simulation tools and methods

- Derivation of models executable on control units

- Simulation and test according valid standards