Why AUMOVIO Engineering Solutions?

Our years of expertise, cutting-edge technologies, and close collaboration between measurement and production ensure every project meets the highest standards of precision, efficiency, and quality.

Turning ideas into reality.

Precision, innovation, and quality across every stage of design, manufacturing, and testing.

ADaM – Advanced Additive Manufacturing

Our ADaM service is not just another printing solution. We combine extensive expertise and experience to cover the entire product lifecycle: concept development, additive design, start-up and ramp-up, validation, and testing. Every task performed by ADaM can meet strict automotive quality standards.

Using our ultra-modern technology park, we realize plastic and metal products with Stereolithography (SLA), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), Digital Light Processing (DLP), Vacuum Casting, and Selective Laser Melting (SLM). This diverse technology set enables highly optimized development and production processes and supports rapid innovation.

Manufacturing & prototyping

Plastic processing: Injection molding, vacuum casting, and thermoforming for diverse materials and complex designs.

Metal processing & milling: Die-casting, turning, milling, bending, wire erosion, and laser cutting. CNC 3–5 axis machines provide high-precision results on plastics and metals, from small components to large workpieces.

Assembly & connection technologies: Laser welding, MIG/MAG welding, adhesive systems, 3D laser welding, polishing, and surface treatments ensure robust, precise assemblies.

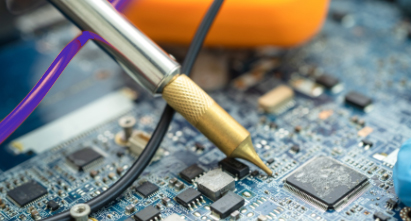

Electronics & circuit boards

Full-service PCB assembly from prototypes to series

SMD population, single-pin insertion, reflow, vapor-phase, and selective soldering

Testing & inspection: 2D/3D AOI, flying probe, manual functional testing

Component procurement & logistics with 6,500+ parts in stock and full coordination of sample orders

Precision measurement & quality assurance

State-of-the-art optical and tactile measurements with <1µm accuracy

3D scanning, reverse engineering, surface roughness, and contour measurement

Expert analysis including metallography and digital microscopy

Detailed measurement reports, best-practice guidance, and ongoing technical support