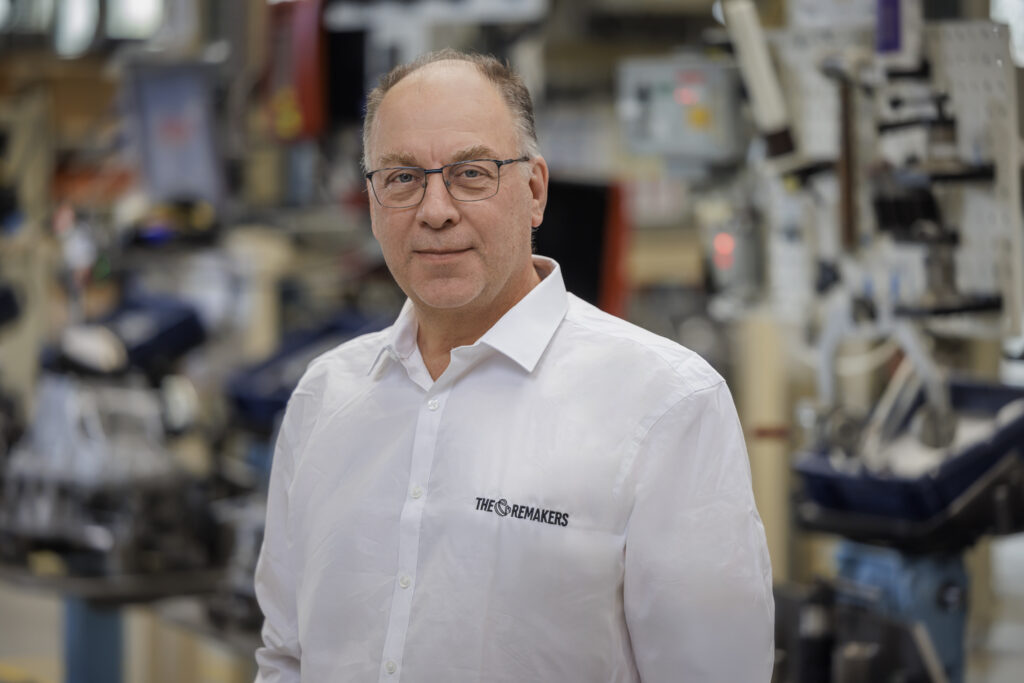

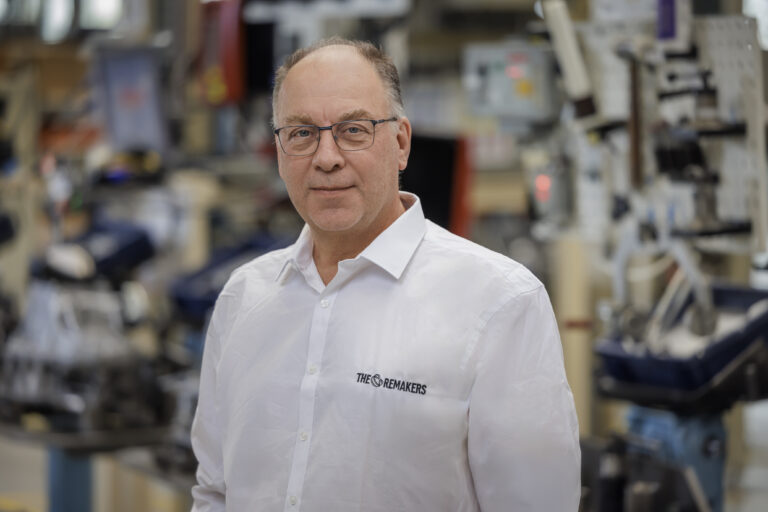

As the automotive industry accelerates toward electrification and sustainability, remanufacturing is emerging as a cornerstone of circular innovation. At the forefront of this movement is THE REMAKERS , a company with over 75 years of expertise, now part of The Future is NEUTRAL Group. In collaboration with AUMOVIO Engineering Solutions, THE REMAKERS is pioneering new approaches to remanufacturing electric vehicle components. We spoke with Rafaël Tréguer, Managing Director of THE REMAKERS, about the company's evolving mission, strategic partnerships, and the challenges of scaling circular solutions globally.

“Our mission is clear,” says Rafaël Tréguer. “We deliver the best remanufactured components to the market. Our leadership in Europe is built on unique processes refined over decades.” With its integration into The Future is NEUTRAL, THE REMAKERS is expanding its reach beyond the Renault Group, aiming to serve the broader automotive ecosystem. “This is a growth opportunity,” he adds, “to bring our expertise to all players committed to circularity.”

“Our mission is clear,” says Rafaël Tréguer. “We deliver the best remanufactured components to the market. Our leadership in Europe is built on unique processes refined over decades.” With its integration into The Future is NEUTRAL, THE REMAKERS is expanding its reach beyond the Renault Group, aiming to serve the broader automotive ecosystem. “This is a growth opportunity,” he adds, “to bring our expertise to all players committed to circularity.”

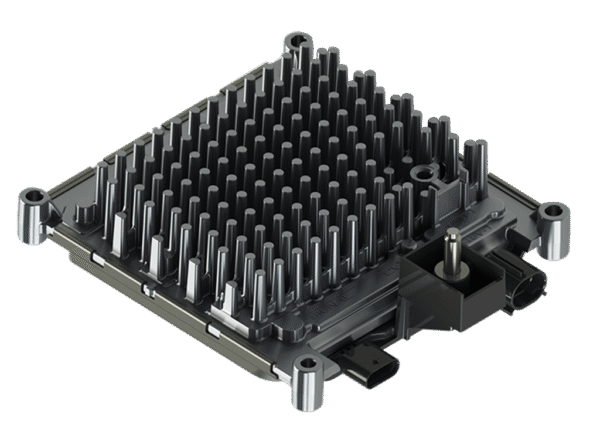

Powering collaboration: the DC/DC Converter project

One of the company’s landmark initiatives is the DC/DC converter remanufacturing project, developed in close partnership with AUMOVIO Engineering Solutions. “Their know-how was essential,” Tréguer explains. “From the start, we knew we needed a partner with high-value technical skills.” The collaboration enabled both teams to meet tight deadlines and deliver results that set a benchmark for future circular economy projects. “It’s a strong example of what’s possible when expertise and purpose align.”

At the heart of this collaboration is the DC/DC converter – a key power electronics component that manages energy flow between high-voltage and low-voltage systems in electric vehicles. As a technology partner in this project, AUMOVIO Engineering Solutions brings deep expertise in power electronics and system integration. Our mission is to enable ethical innovation through engineering excellence and collaborative development. By combining our technical capabilities with THE REMAKERS’ remanufacturing know-how, we’ve helped shape a solution that is both technically robust and environmentally impactful.

This partnership has enabled the launch of Europe’s first remanufacturing offer for EV motors and power electronics units, delivering a solution that is up to 30% more cost-efficient than new parts, while maintaining full performance and reliability.

THE REMAKERS has set an ambitious goal: grow the business by 50% by 2030. Tréguer sees collaboration as key to achieving this. “Electrification is reshaping the industry. Our pioneering expertise positions us to scale rapidly, and AUMOVIO is a crucial partner in this strategy. Together, we aim to remanufacture at high volumes and stay ahead of the curve.”

Tackling EV complexity

In a major milestone, THE REMAKERS recently launched Europe’s first EV motor remanufacturing offer. But expanding into EV components like power electronics brings new challenges. “We had to upskill our teams across engineering, manufacturing, and quality,” Tréguer notes. “The processes are different from traditional mechanical ones, and managing component diversity and obsolescence is complex.” Ensuring compatibility and “virginisation” of remanufactured parts for electric powertrains adds another layer of technical rigor.

With circular solutions already available across Europe, THE REMAKERS is now looking beyond the continent. “Each country has its own context,” Tréguer explains. “We need to understand local needs and remain competitive while maintaining our high standards. Price and adaptability are key.”